Home » Non-Destructive Testing » Traditional Radiographic Testing (RT)

TRADITIONAL RADIOGRAPHIC TESTINT (RT)

Film Development Laboratory

Industrial Radiography Using Elliptical Technique

Bunker for Radiographic Inspections

Bunker for Storing Radiographic Equipment

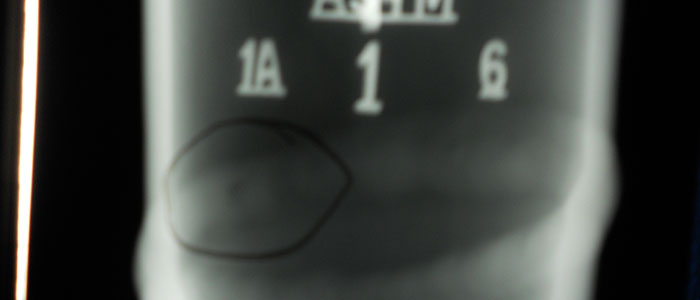

Gilardoni Equipment

CHECKABLE PRODUCTS

The checkable products can be: welds, rolleds, forgeds, drawns, castings, machined.

ADVANTAGES

The advantages are the high degree of reliability and the ability to also highlight internal defects. Moreover, radiographic testing can be documentable in time.

DISADVANTAGES

The limits are the impossibility of use on materials that are opaque to radiation or with a particularly complex geometry, and the thickness of the object to be examined. Even the most powerful X-ray does not exceed thicknesses greater than 80 mm of steel (180 mm for gamma rays). In addition there are inevitable problems related to radioprotection security.

AVAILABLE EQUIPMENT

- GILARDONI 350 Kv/6

- GILARDONI 300 Kv/6 P

- GILARDONI 300 Kv/5

- GILARDONI 200 Kv/5

- GILARDONI 300 Kv MHF 300M POC

- GILARDONI 200 Kv MHF 200 POC

- GAMMA-RAY SOURCES: IRIDIUM, SELENIUM, COBALT

For materials with an higher thickness, such as forgeds and welded sheets for the nuclear industry, we use a linear accelerator of 2 Mev power.

Centrotest Srl has got 2 bunkers for carrying out radiographic checks and for the storage of radiographic X-ray equipment, and 2 laboratories (including a mobile one) for films development.

MAIN REFERENCE STANDARDS

- EN462, EN 1435, EN 12517, EN 17636

- ASME V Art. 2

- ASTM E 1742, ASTM E 747