Home » Non-Destructive Testing » Non-destructive testing on reinforced concrete » Sonreb method

SONREB METHOD

TECHNIQUE THAT IMPROVES RESULTS’ RELIABILITY FOR ULTRASONIC AND SCLEROMETRIC METHODS

THE METHOD

The term Sonreb , created merging the terms “Sonic” and “Rebound”, identifies the salient features of the control technique, which combines measuring ultrasound propagation speed with measuring the sclerometric rebound index. This combined methodology arouses interest because, compared to other methods of non-destructive or destructive control, it has advantages like ease and rapid execution . Sclerometric and ultrasonic tests, although useful for the concrete’s characteristics assessment, can return data influenced by factors that can make them less reliable when considered separately.

Current regulations allow that the destructive tests can be integrated by a series of non-destructive tests, of documented reliability, provided that the results are calibrated on the basis of those obtained by destructive tests. In situ investigations are needed to define the knowledge level that the project manager will adopt, on the basis of which he will determine the confidence factor to be taken in the analysis and testing.

If the results ensures the presence of repeatability values at different levels of the building, this establishes the opportunity to quantify the number of destructive and non-destructive tests.

PRINCIPLE AND TEST PROCEDURES

Application of the Sonreb method requires evaluation of local values of ultrasonic speed V and of rebound index S, from which you can get an estimate of the strength of Rc concrete in site, using expressions like:

Rc = a⋅Sb⋅Vc

– Rc is the cubic compressive strength in [MPa];

– S is the sclerometric index;

– V is the ultrasonic speed [m/s];

– coefficients a, b, c allow to best correlate the experimental direct data. Consequently, they differ in a significant way in terms of result.

For the Sonreb combined method, the dependent variable is Rcub, while the independent variables are respectively the average sclerometric index Ir and the ultrasound propagation speed Vus. The correlation that follows is expressed in the following way:

Rcub = a·Ir·b·Vus·c [MPa, m/s]

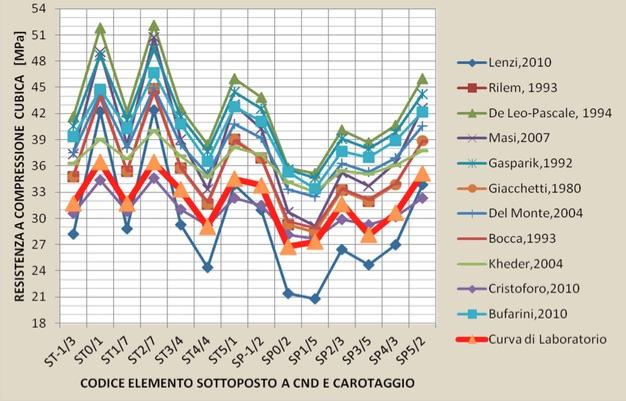

Parameters a, b and c represent the values to be determined to calibrate the correlation law to the specific case. Having now available, in addition to non-destructive parameters, also the laboratory values, even for the same structural element, it’s interesting to see in what position is placed (with respect to the curves created with the expressions of the literature) the curve that we can call of laboratory. Of course to do this we need to previously have turned the cylinder compression resistances Fc in cubic compression resistances Rc.