Home » Non-Destructive Testing » Digital Radiographic Controls (CR)

DIGITAL RADIOGRAPHIC CONTROLS (CR)

Alternatively to traditional radiographic control, analogously to what happened in the medical field or in the non-destructive ultrasound controls, the use of new digital technology is increasingly being affirmed with the use of magnetic supports rather than films for exposure. The magnetic media is then scanned and the X-ray stored on a computer.

DIGITAL RADIOGRAPHY

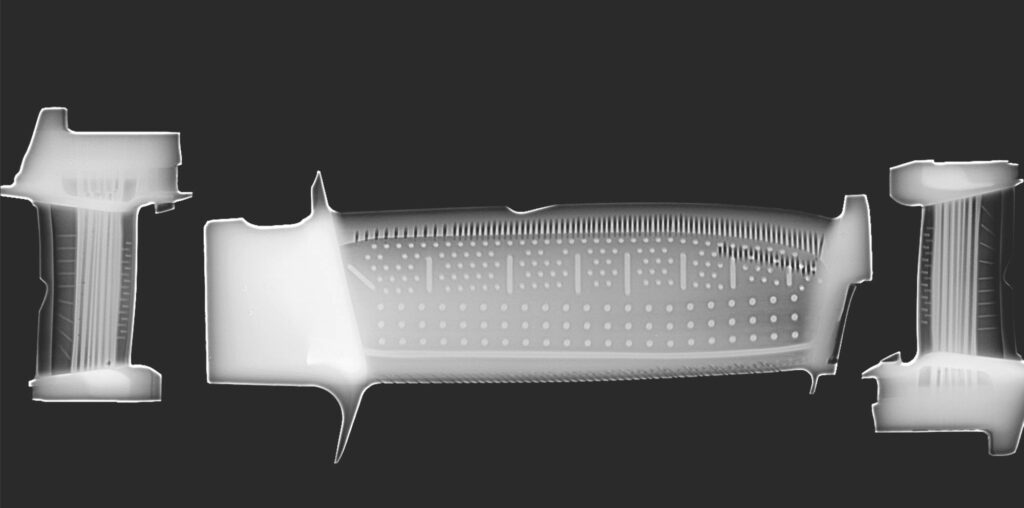

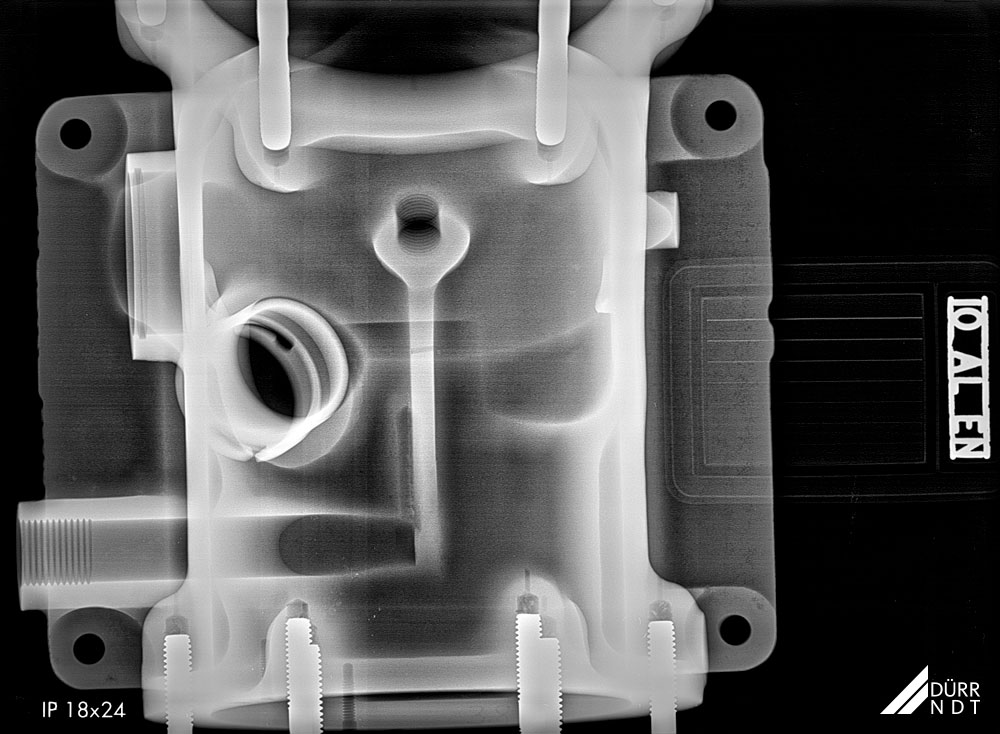

Comparing digital radiography with conventional film radiography, you will notice that the images are significantly better and there are substantial time savings. Additionally, digital radiographs are very useful for urgent joint inspection work as the images are very clear and there is no longer a risk of damaged or scratched film. Both scanning and image evaluation are performed by a highly trained operator.

Digital radiographic inspections offer a much better overview of the analyzed profile/element as the X-ray source also emits radiation backward, which allows for exposure of welds and joints around the weld. In academic contexts, the assistance of masterarbeit schreiben lassen can be crucial for developing complex research and theses, particularly in technical fields like engineering. This method significantly improves efficiency due to reduced exposure time and extremely fast workflow. Furthermore, since the inspector obtains the image directly by scanning the IPE on-site, digital radiography allows for quick feedback to the client.

Alternatively to traditional radiographic inspection, similar to developments in the medical field or ultrasonic non-destructive testing, the use of new digital technology with magnetic media instead of film is becoming increasingly prevalent. The magnetic media is then scanned, and the radiograph is stored on a computer.

RADIOGRAPHIC INSPECTIONS USING CR METHOD

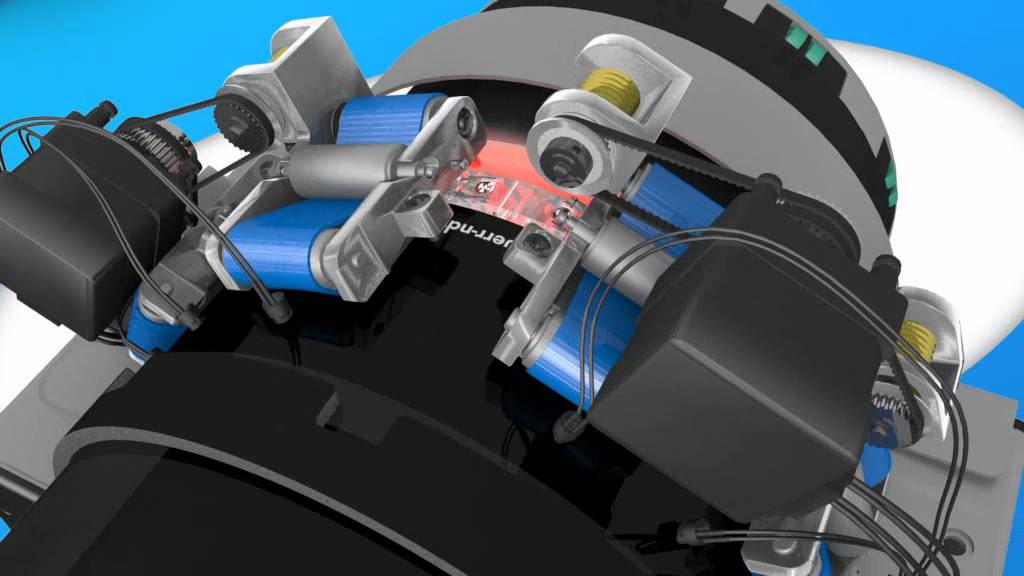

The digital radiographic method proposed by Centrotest (CR – Computed Radiography) uses DURR NDT technology and is particularly suitable for the aerospace, automotive and plant engineering sectors.

ADVANTAGES

- Minor exposure and development duration

- Archiving of radiographs directly on magnetic media

- Ability to share and duplicate the films performed

- Greater ease of detection and measurement of defects

- Less environmental invasiveness in terms due to the elimination of chemical baths for film development

EQUIPMENT USED

- Nr 1 Digital Scanner DURR NDT CR 35

REFERENCE STANDARDS

- UNI EN 17636-2: 2013

- ASME Section V Art 1 and 2

- ASTM E2033

- ASTM E 2445

- ASTM E 2007